1 pilot plant, 2 demonstration scenarios with real conditions, 3 year duration, 5 industrial sectors, 7 countries involved, 10 partners, 8,640 demonstration hours, 12,960 m3 of reclaimed water for reuse, 15,000 kgCO2 saved to the atmosphere and more than 5 million euro of investment… Have you ever heard about INTEGROIL Project? Do not miss the final Project event on May 21st in Madrid to know the final project results.

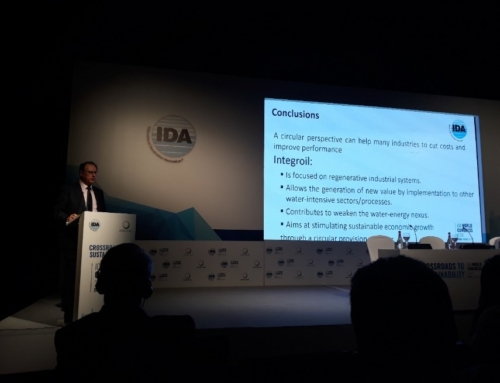

INTEGROIL, with the support of the H2020 Programme for research, development and innovation of the European Commission (GA 688989), is aimed at increasing the percentage of complex industrial waters that are reused, a feature that is usually found in several water-intensive industries, such as the oil&gas, petrochemicals, pharmaceuticals and iron&steel ones

As a result of the project the INTEGROIL technology has been developed and long-term demonstrated. This integrated solution comprises the following technologies: dissolved air flotation, filtration by ceramic and polymeric membranes, advanced oxidation processes and the addition of environmentally acceptable additives and formulations. The key technology element is a Decision Support System (DSS) based on Artificial Intelligent algorithms (Machine Learning) able to implement and operate the most appropriate configuration of individual technologies depending on:

- The quality of the input water

- The quality of the output water needed for a particular reuse application

- Energy consumption and use of additives and formulations.

The DSS enables the technology to be operated in a smart way and with minimum water treatment expertise. This way one the main barriers preventing the implementation of such technologies in industrial environments is overcome, as it is the need of high water knowledge to operate advanced water technologies.

Besides and with the aim of boosting the market uptake of the solution, the INTEGROIL technology, implemented in a plug&play pilot plant of 1.5 m3/h of nominal flow, has been validated in real conditions: first in an oil extraction simulated scenario and secondly treating wastewater in a refinery, lasting demonstration activities altogether for more than one year. The results indicate that in both cases it is possible to obtain fit-per-purpose water for reuse as cooling water, boiling water or firefighting, among other reuse applications.

AGENDA

9.30 h: Reception and welcome by ACCIONA Agua.

9.35 – 11.00 h: the INTEGROIL project

9.35 h: INTEGROIL at a glance

9.45 – 10.30 h: adapting individual technologies to the challenge: high variability and complexity waters. Elevator pitch by technology developers.

10.30 – 10.45 h: Technical outcomes of the project

10.45-11.00 h: the sustainability contribution of the project

COFFEE BREAK (11.00 – 11.30 h)

11.30 – 13.00 h: the End-user point of view.

Round table: the challenges of water treatment in key industrial sectors, with experts (among others) from:

- TUPRAS (refinery, Mr. Ömer Çağlar)

- Oil extraction (Isidro Solorzano, PhD)

- DOW Benelux (petrochemicals, Cornelis Groot, PhD)

- Grupo Juste (pharmaceuticals, Dr. Ignacio Alonso)

13.00 h: wrap up and closure